Trumpf has developed a dual optics (Dual PFO) that reduces cycle times in automated welding by up to 30 percent, for example for the hairpins of electric motors.

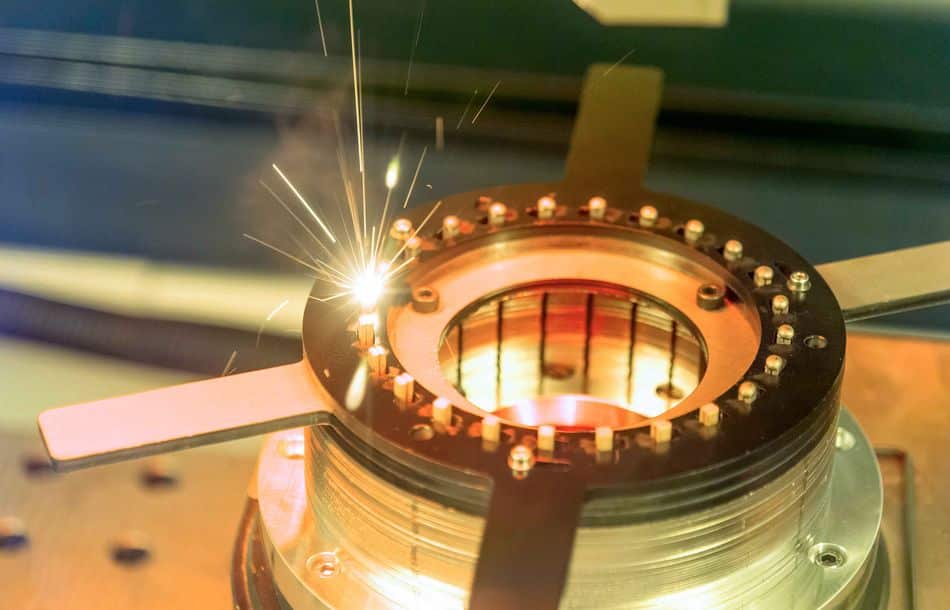

Welding the hairpins of electric motors must always be of consistently high quality. Otherwise, the electric motors will be defective. Since the hairpins are very fine, this welding process is considered very demanding. To achieve high quality, a PFO always measures the position of the component first, before the welding process begins. Unlike a normal PFO, the Dual PFO measures and welds in parallel. “Users save a lot of time and money in their production unit as a result. The dual optics can also be combined with our new image processing, which is based on artificial intelligence. This increases the productivity of the Dual PFO even further,” says Matthias Beranek, Automotive Industry Manager at Trumpf.

The Dual PFO has twice the working field of a normal PFO. The solution is therefore particularly suitable for processing large components such as electric motors. Users can weld these with the Dual PFO without moving the workpiece or the focusing optics themselves. “The system is versatile and is also suitable for other large components, such as batteries for e-cars,” says Beranek.

Source: Trumpf