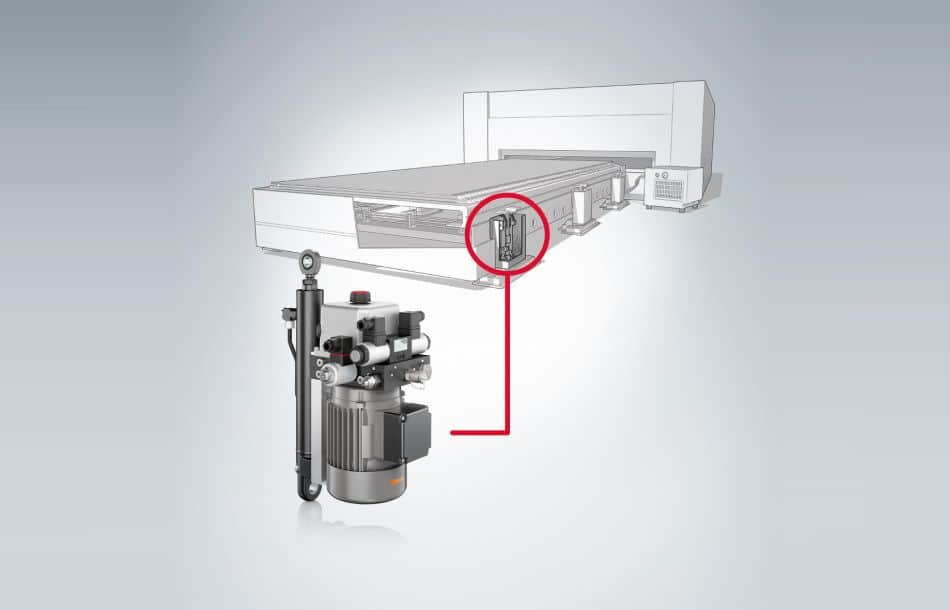

For the uniform lifting and lowering of pallet changers in laser cutting systems, it is crucial that all hydraulic cylinders move perfectly synchronously. The new decentralised solution LiftAx from Hawe Hydraulik realises synchronous movement with high precision and also offers advantages during installation and commissioning.

The plug & play unit consisting of hydraulic cylinder and hydraulic power pack type LiftAx is mounted at each lifting point of the pallet changer. With an external dimension of 415 x 338.5 mm, it is compact and requires little installation space. A separate piping of the individual lifting units among each other is completely omitted. Due to the ready-to-connect delivery, installation and commissioning take place very quickly. In case of service, a unit can be replaced or repaired separately without having to dismantle the entire lifting table.

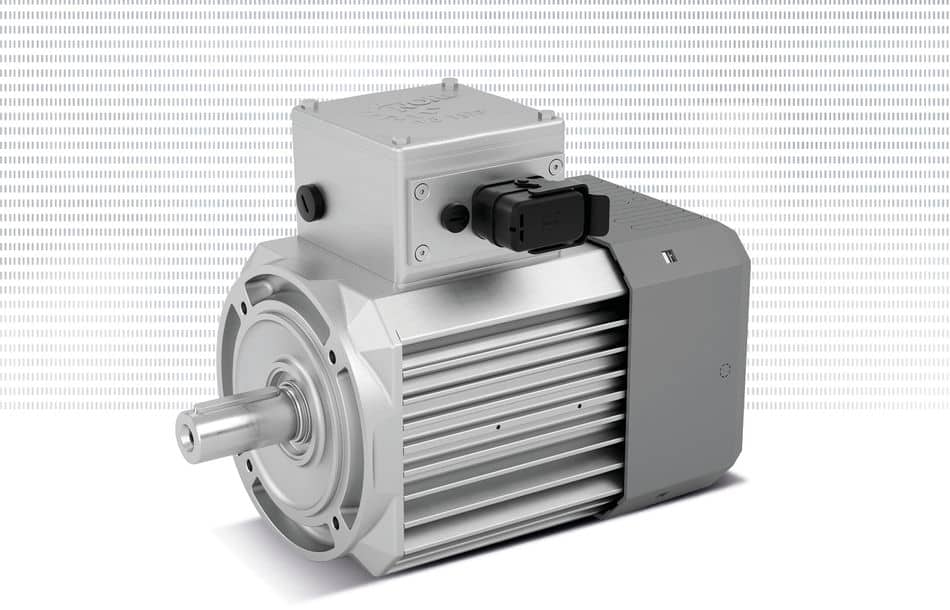

The structure and functional principle of the LiftAx are convincingly simple: Each hydraulic power pack consists of a tank with 1.75 kW motor and external gear pump. The required system pressure is set at a pressure-limiting valve. By means of a flow control valve and intelligent switching, it is ensured that the preset flow volume is exactly adhered to both when extending and retracting the cylinders. The leakage-free directional seated valve ensures that the cylinder position is securely maintained.

Source: Hawe