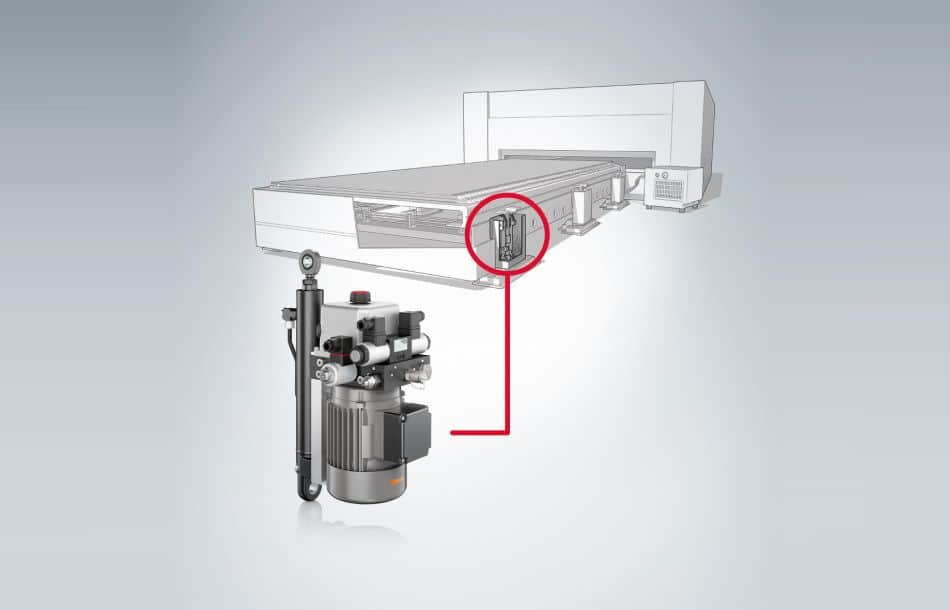

Moog has launched a new electric linear actuator solution consisting of a new, low-maintenance servo drive from the MG series, a DX2020 servo drive and pre-assembled cabling.

Quick replacement of pneumatic and hydraulic cylinders

The form factor of the new MG actuators is based on conventional pneumatic or hydraulic cylinders. By coupling the new MG actuators with the company’s Servosoft sizing tool, a machine builder can retrofit existing systems with optimally sized solutions based on the right MG actuator together with the DX2020 servo drive and its energy management components.

Thanks to the extended possibilities of an electromechanical control system, performance can be achieved that would be difficult to achieve with hydraulic solutions or impossible with pneumatic solutions.

Another advantage of the manufacturer’s new electromechanical actuator solution (EMA) is the potential for cost savings. If you compare the cost-benefit ratio of the EMA solution with that of typical hydraulic and pneumatic systems, EMA saves 25 % and 50 % respectively.

With same dimensions, more than twice the force of prior Moog designs

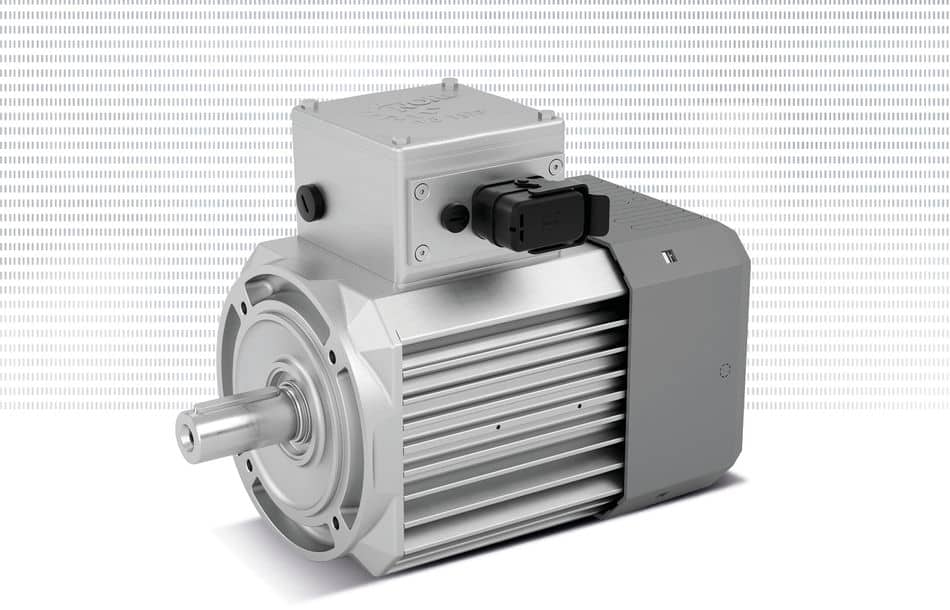

At the heart of the manufacturer’s electric drive solution are the newly developed MG series servo actuators, which offer smooth, precise movements and a long service life even with high payloads and peak forces of up to 170 kN. Compared to hydraulic actuators, the actuators are low-maintenance, more environmentally friendly and more stable and eliminate the disadvantage of pressurized oil lines.

Because they are coupled with position-controlled Moog servo drives, the company says customers get greater precision in linear positioning and can program the MG series with specific motion profiles that perfectly suit each application (e.g. reducing mechanical stress, speeding up the duty cycle, reducing noise, etc.).

The actuator design includes an optional internal screw support, an alternative that helps reduce the negative impact of small misalignments on screw life. And in some mounting positions, for example when mounting with rod eyes on both sides or with ears on the side, the new design mitigates the effect of gravity on the actuator.

DX2020 and associated cabling

The DX2020 family of servo drives also contributes to the outstanding performance of Moog’s electric actuators. With single, multi-axis and remote axis options (and combinations thereof), the DX2020 can control the EMA with high speed and high accuracy motion. In addition to excellent control performance, a wide range of current ratings up to 198 Arms and a high overload factor, the DX2020 series offers multiple fieldbus interfaces such as CAN, EtherCat, Profibus or Profinet.

The Moog electric actuator solution is rounded out by the availability of pre-engineered sets of cables in different lengths, which support quick and easy installation on each machine.

Close customer collaboration with direct access to global Moog experts

“We focus on delivering the best performance for each application by closely collaborating with our customers every step of the way,” says Erik Stephan, Moog specialist for EMA. “The new MG Series based solutions will enable considerably more electrical solutions benefitting our customers and contribute to a more energy-efficient and sustainable future.”

Source: Moog