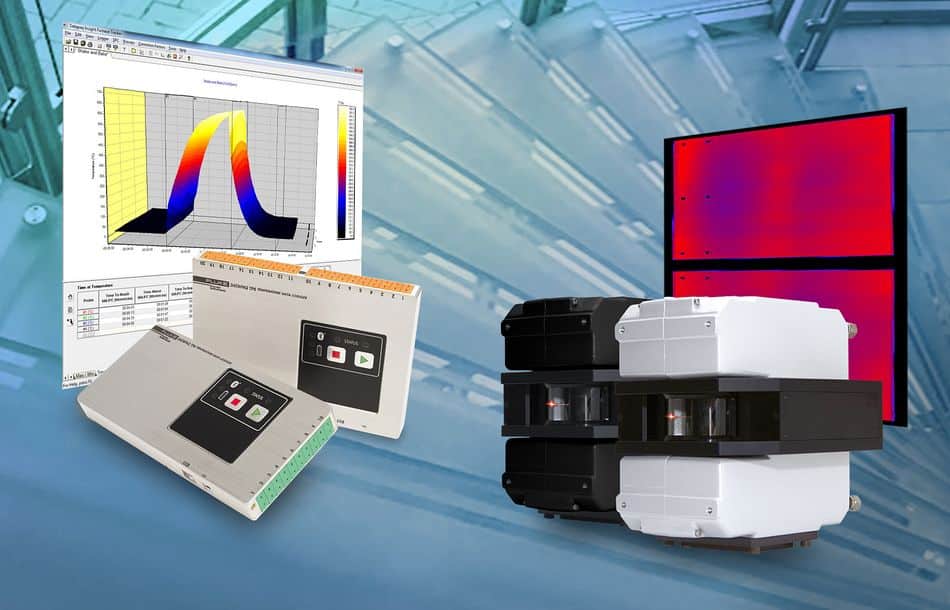

Fluke Process Instruments offers temperature monitoring solutions for quality control in glass manufacturing, forming and coating processes.

The lineup features various infrared sensors and thermal imaging systems for non-contact temperature measurement and analysis. Real-time feedback and comprehensive connectivity options ensure easy integration in factory control systems. Line operators receive real-time process information to help them increase plant productivity, improve ROI and minimize operating costs. The MP Linescanner series provides live thermal imaging of moving processes such as float glass manufacturing and flat glass tempering, checking for temperature uniformity as well as physical damage and detecting hot spots and cold spots. For monitoring the temperature curve inside the furnace, Datapaq dataloggers are available, which track temperatures via thermocouples attached to the glass sheet surface. The manufacturer furthermore offers a full range of infrared pyrometers with suitable wavelengths for all kinds of applications in the manufacture of bottles, vials, ultra-thin drawn glass for touchscreens and much more.

Source: Fluke